- Frontpage

-

New

Tilbage

Luk -

Tools & Machines

Tilbage

LukTools & Machines

-

Se alt i Tools & Machines

- New

- Gift Card

-

Hand Tools

Tilbage

LukHand Tools

-

Se alt i Hand Tools

- Pliers

- Saw Frames & Blades

- Precisions Files / Handles for needle files

- Gravers / Handle for gravers

- Calipers / Measuring

- Dividers / Engineers Squares

- Magnifier / Glasses

- Shears

- Tweezers

- Soldering Tweezers

- Hammers

- Ring Sticks / Ring Gauges / Wrist Meters

- Setting & Engraving Equipment

- Joint Cutters / Profile Cutters

- Special Tools

- Reamers / Pin Vices

- Stamps

-

Drills / Cutters / Miniature brushes

Tilbage

LukDrills / Cutters / Miniature brushes

-

Grinding / Polishing

Tilbage

LukGrinding / Polishing

-

Metal Forming

Tilbage

Luk -

Soldering / Melting Equipment

Tilbage

Luk -

Machines

Tilbage

LukMachines

-

Se alt i Machines

- Lathes

- Electroplating / Electropolishing

- Engraving / GRS

- Engraving Machines / Laser Engraving

- JURA by GRS

- Compressors

- Magnetic Tumbler / Rotary Tumbler

- Micromotors / Flex Shaft motors

- Ring Stretchers / Ring Bending Machines

- Blasting

- Grinding / Polishing / Brass

- Pickling Units

- Draw Bench

- Extraction unit

- Ultrasonic Cleaners / Steam Jet Cleaners

- Rolling Mills

- Vivacolor

-

Wax / Casting

-

Literature

Tilbage

LukLiterature

-

Equipment

- Watchmaker Tools

-

Chemicals / Cleaning

Tilbage

Luk

-

Findings

Tilbage

LukFindings

-

Se alt i Findings

- New findings

-

Pearl Clasps / Parts

Tilbage

Luk -

Settings / Pendants

Tilbage

LukSettings / Pendants

-

Brooch

Tilbage

Luk -

Ear Parts

-

Cufflinks / Tie Clips / Tie Slides / Button Backs

Tilbage

LukCufflinks / Tie Clips / Tie Slides / Button Backs

-

Clasps

-

Chains

Tilbage

Luk -

Assorted Findings

Tilbage

Luk

-

Diamonds & Gemstones

Tilbage

LukDiamonds & Gemstones

-

Courses

- Log ind

- Min konto

- Log ud

-

Vælg sprog

Tilbage

LukVælg sprog

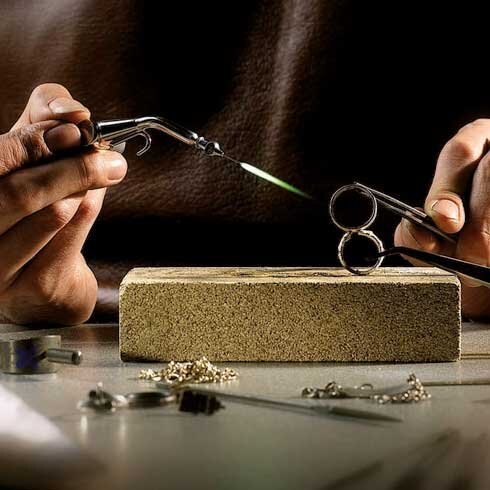

No gas: Why Lötstar is one of the safest soldering machines

At Aktiv Guld we primarily offer equipment and products that provide considerable benefits to goldsmiths and silversmiths. In this regard, we focus on efficiency, ergonomics, health, safety and the chance to reduce costs. MIG-O-MAT and Lötstar share these values, with this fantastic firm boasting 50 years of knowledge and experience of soldering machines.

A robust machine on hydrogen

Since 1972, MIG-O-MAT has developed forward-thinking welding and soldering technologies for both the goldsmith and silversmith sector. Lötstar, in particular, gives a nod to the future, as the micro-flame which does the soldering runs on hydrogen that is produced via electrolysis. This means that an energy source is used that will never run out and where there is no need for the inconvenience or cost of gas cylinders when working with the machine.

Furthermore, Lötstar is robust, as the electrolyte and other components only rarely need to be replaced, in addition to which the electrolysis process ensures greater safety with respect to fire and explosion hazards.

Long-term benefit

With 45 years of knowledge and experience of the machine, firstly as a goldsmith and later as a sales consultant at Aktiv Guld, Bernd Stahlhacke is something of a guru with regard to MIG-O-MAT’s machines, but he also acknowledges that you have to be prepared to adapt to the new machine

“In the goldsmith and silversmith business, we tend to be rather conservative and would prefer to continue using what we’re familiar with. So of course you have to learn to use a Lötstar if you’ve been used to a machine that runs on gas - in addition to which it represents quite a significant investment. It may well take a couple of weeks to get used to a new tool, but I must say that it’s really worthwhile in the long term with regard to quality, efficiency and safety - and above all if you want to save money and value convenience”, says Bernd Stahlhacke.

Why you should choose a machine from Mig-O-Mat:

1. You get one of the safest machines on the market

A Lötstar machine produces gas (hydrogen) itself via electrolysis. This cuts out the inconvenience of gas cylinders, whilst only emitting water vapour when the machine is being used. With gas, which is typically oxygen, propane or similar, there is a safety risk, as it can explode if, for one reason or another, the flame should get sucked back through the machine.

Lötstar is one of the safest machines on the market in relation to similar hydrogen machines, as there are almost no plastic hoses in the machine. Plastic hoses are often the most vulnerable component in this type of machine. In this case, however, the amount of plastic is kept to a minimum (e.g. to measure pressure).

2. You will see a reduction in costs

A Lötstar saves you money in the long run. In traditional soldering processes there is a constant cost related to replenishment of gas and transport of gas cylinders, which you do not need to worry about with a Lötstar. This means that not only are costs reduced, but you also save precious time.

3. You get an efficient and quiet machine

With a Lötstar you never end up with an empty gas cylinder. Electrolysis means that gas is produced on a continuous basis. For the largest model (Lötstar 301), no less than 300 litres of gas can flow through each hour. All you have to do is fill up with distilled water a couple of times a month, depending on how much the machine is used.

The machine is designed for permanent use and is very quiet during operation.

About Mig-O-Mat

Since 1972, the German company Mig-O-Mat has developed forward-looking welding and soldering technologies for e.g. the gold and silversmith industry. With more than 50 years of knowledge, Mig-O-Mat is the market leader in plasma welding and micro flame brazing with a high level of quality, process reliability and efficiency.

Shop online

Soldering and welding unit Lötstar 301, MIG-O-MAT

Lötstar 301 is a soldering and welding unit with own gas production by the electrochemical way of electrolysis. The temperature and the energy of the micro flame are adaptable to a broad area of applications.

Login

As a customer of Aktiv Guld, you can quickly and easily make your purchases online, regardless of whether it is from a computer, smartphone or tablet.

Login >

If you are not already registered as a user, you can do so here: