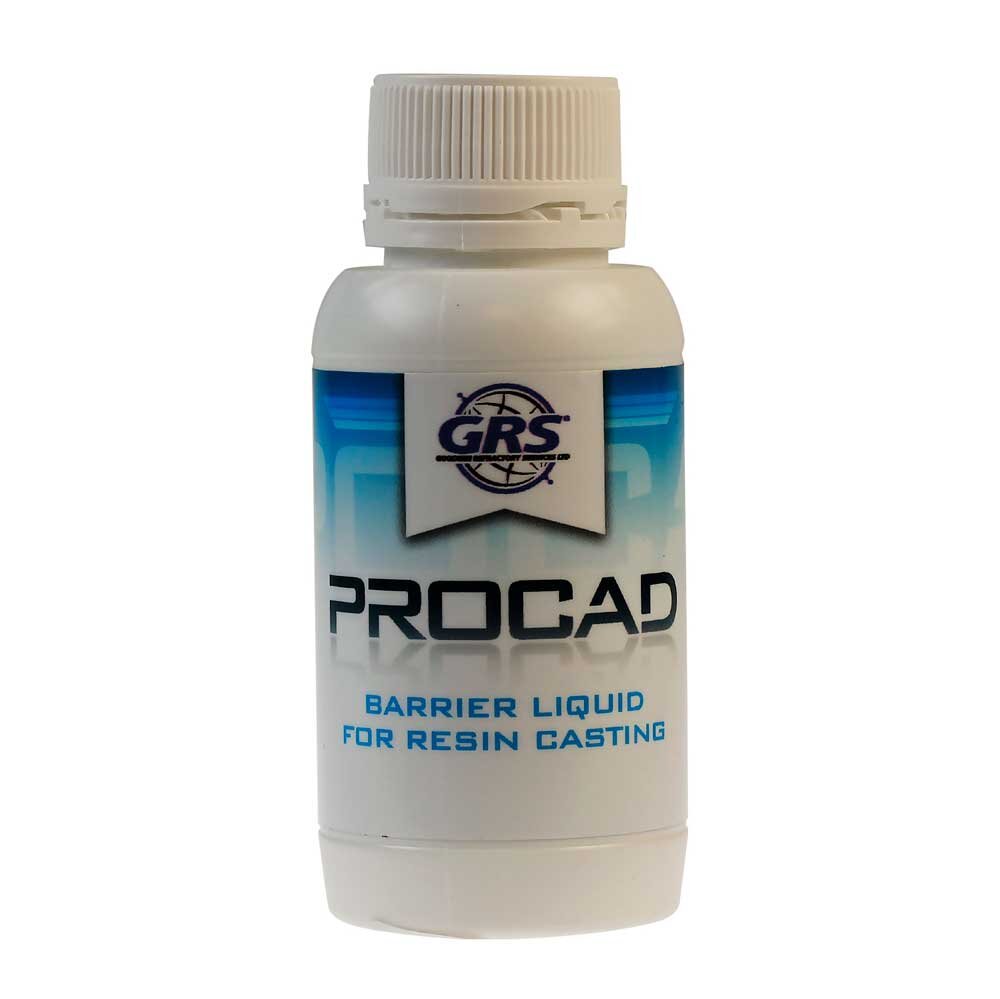

PROCAD - barrier liquid for resin casting

Procad – barrier liquid for resin casting

Procad has been developed, tested and approved for two applications when producing resin pieces (3D print). Resin pieces are produced for either creating trees to direct cast the resin pieces or to manufacture rubber moulds using the resin piece as master pieces.

Direct Casting of Resin Pieces

The most common problem when direct casting of resin pieces is rough surfaces and inclusions. Resin expands and boils disturbing the surface of the investment powder creating the rough surfaces.

To avoid this the resin piece can be dipped in Procad between 5 to 10 times. The amount of time a resin pieces should be dipped in Procad depends on the design. It is recommended to reduce the dipping if the piece is small, contains tiny holes, recesses for stone setting or is filigree in design.

Rubber Moulds Manufactured with Resin Pieces

It is common to find that the resin are stuck to the rubber which affects the cutting technique and design, making the mould unsuitable to inject wax pieces into them.

By dipping a resin piece into Procad once or twice before inserting it into the rubber before vulcanizing will prevent this from happening. The Procad coats the resin pieces and creates a barrier to stop the rubber from migrating into the pores or sticking to the surface.